Technology

A GC like you have never seen before!

What do you expect from a GC? Surely an oven in which the separation column is located. You are in for a surprise: The Hyperchrom GC has no oven!

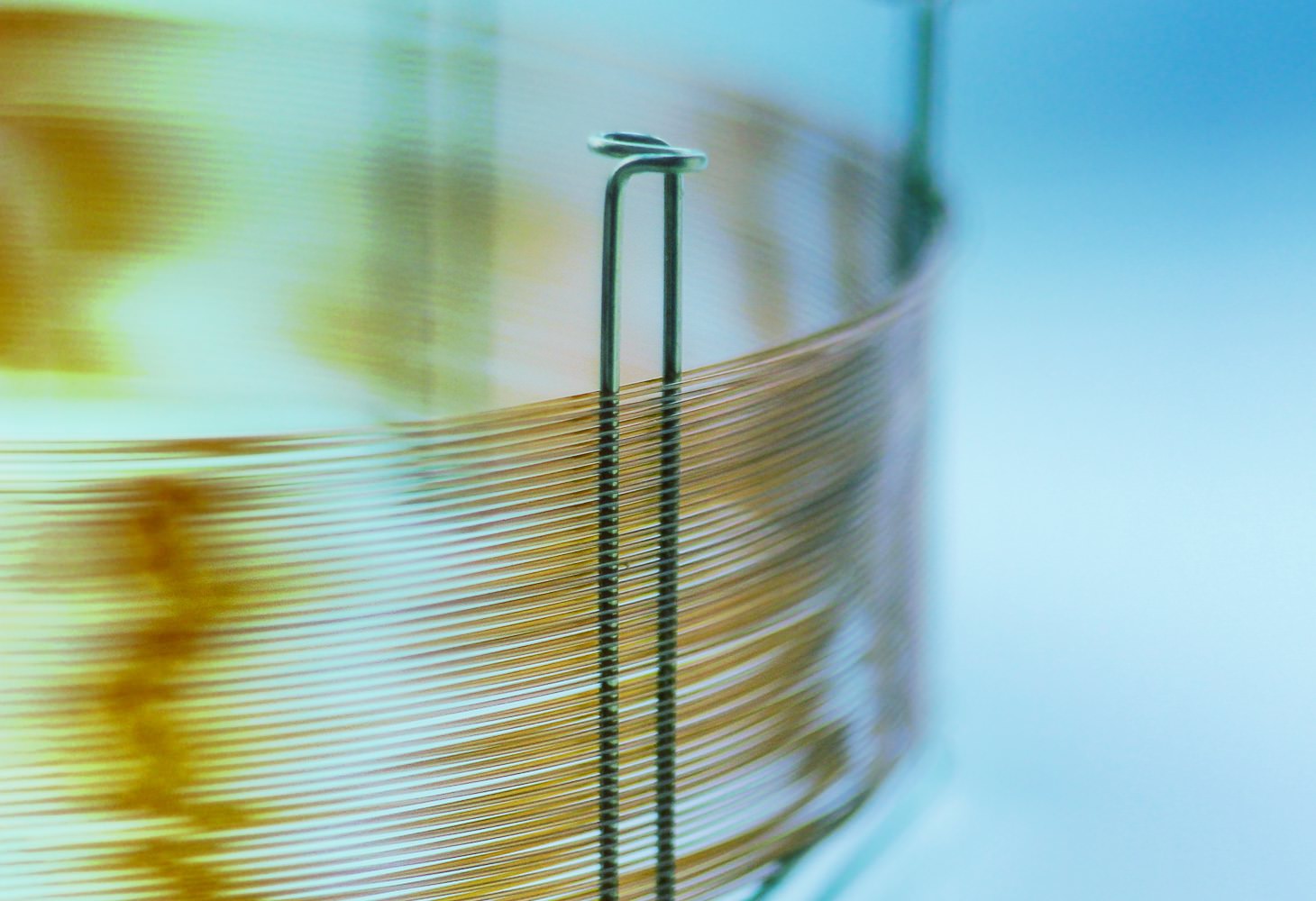

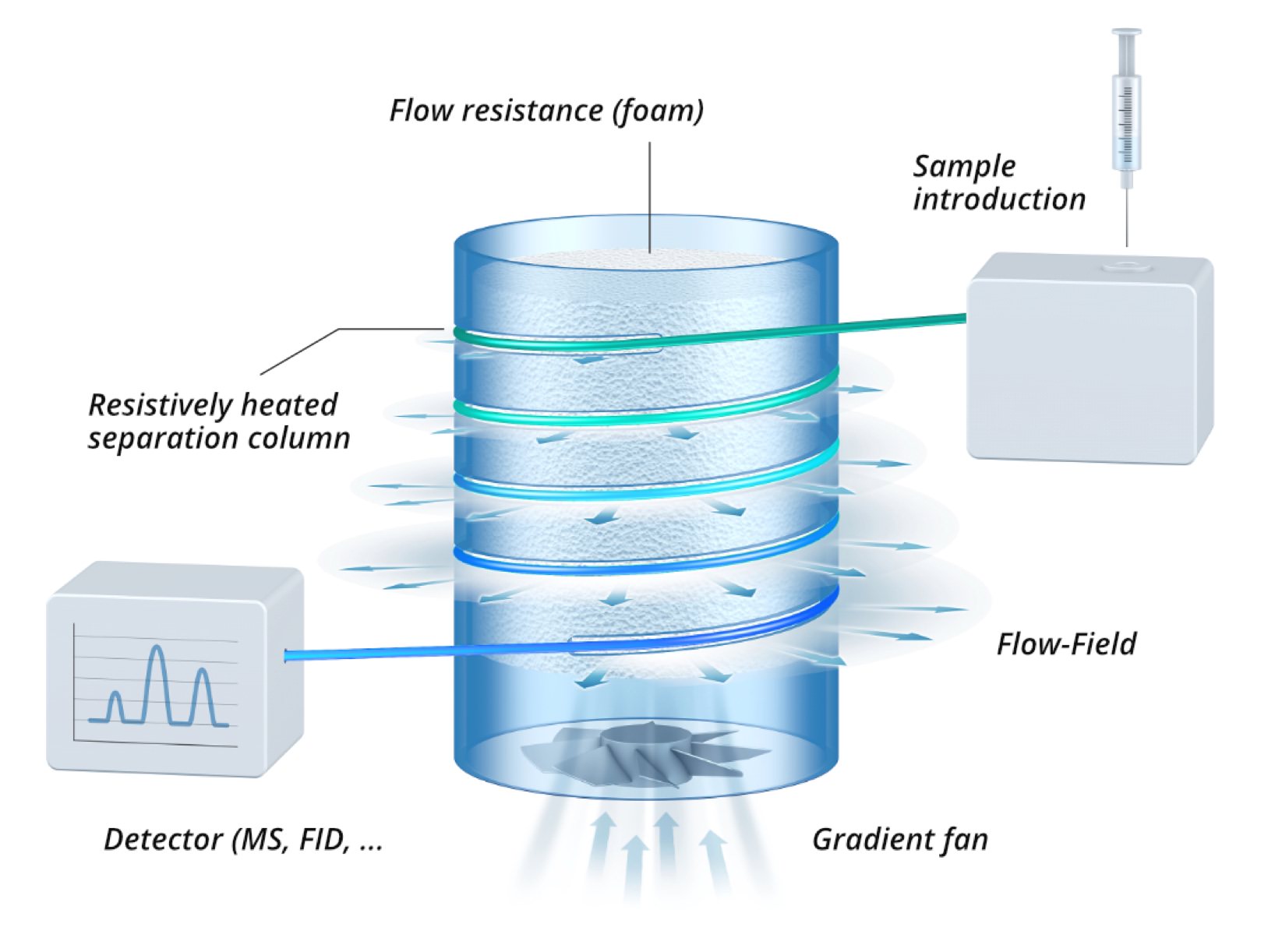

The separation column is heated in a thin steel capillary. This is extremely fast and consumes very little energy. The very special feature, however, is the added possibility of using a continuous temperature gradient. With the temperature gradient, the signals are focused and shaped. At the same time the elution temperatures are greatly reduced. The temperature gradient is generated by an ingeniously simple trick. The heated capillary lies in a flow field which is generated in such a way that the flow velocity increases continuously. Thus, the inlet of the separation column is hotter than the outlet. While the principle is simple, many technological challenges have had to be solved before this process worked as stably as conventional oven GCs.

Stability of retention times is a key requirement of a GC. Of course, this is more difficult to achieve in the seconds range than in the minutes range of conventional GCs. HyperChrom's solution is again very unusual: water cooling. The carrier of the heated capillary is kept at a constant temperature via a coolant circulation. As a result, the environment of the capillary is not dependent on changing outside (laboratory) temperatures. But there is another big advantage associated with cooling. The gas chromatography can now start at 20°C. Without a special device and hardly any delay.

Technically, the cooling is realized with additive manufacturing of the column's support. Using selective laser sintering, internal cooling channels are printed into the wall along the flow channels.

Flow-Field Thermal Gradient Gas Chromatography (FF-TG-GC)

Creating a smooth thermal gradient along a separation column is a challenging task. A 'Flow-Field' is achieved by placing a flow resistance between an air fan and the helical channels and heated capillary sheath. Thermal loss of the resistively heated separation column depends on the velocity of the air flow.

Flexible programming of both the air flow and heating current is used to control the temperature and magnitude of the thermal gradient. This new degree of freedom enables novel measurement methods.

Temperature & Gradient Programming

The temperature curve can be programmed to scale of seconds as opposed to the scale of minutes for conventional GCs. Multiple ramps, iso-thermal phases and even negative ramps are possible. The temperature gradient can be increased or decreased depending on the requirements.

Peak Focusing

In classical GC, peaks are broadened by diffusion. This effect is counteracted by our innovative peak focusing. This is achieved by the thermal gradient applied on the separation column. The thermal gradient creates a velocity gradient within the separation column where the front is slower than the tail. Consistent Gaussian-form peaks can be achieved with FF-TG-GC! Drastically reduced elution temperatures are advantageous when analysing unstable substances. Lower operating temperatures also extend the column's lifetime and stability.